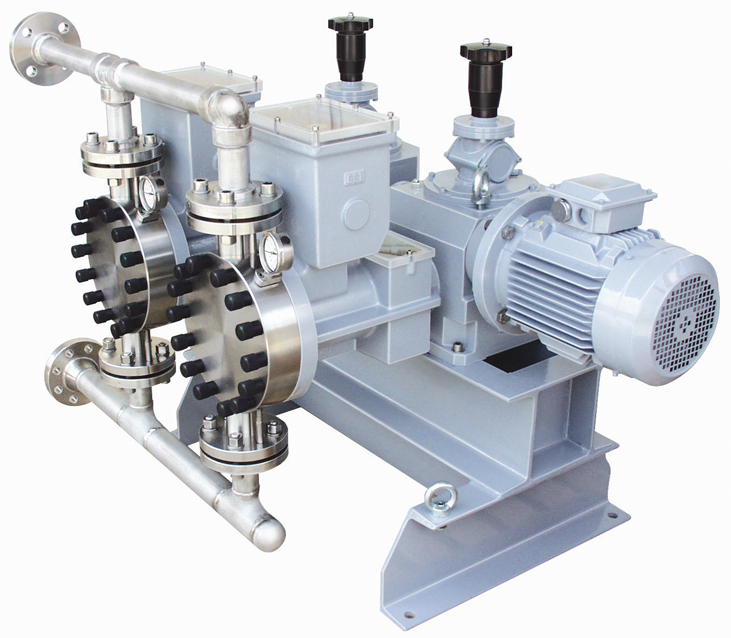

Eco Gearchem GA – GH

ECO Gearchem pumps offer the reliability needed to safely handle clear lubricating and non-lubricating liquids. Extensive material availability provides versatility for pumping low or high viscosity fluids over a broad range of temperatures, pressures, and corrosive substances.

Industrial Construction

At the heart of each ECO Gearchem pump are two tightly toleranced,machine-generated spur gears consisting of a drive and an idler gear.Self-priming capability is accomplished by our closely toleranced gears, which evacuate air from the suction piping. Gearchem pumps provide linear, pulsation-free flows, and the pumps are bidirectional. This easily allows the flow direction to be changed.

Application Expertise

Typical applications for this self-priming, external-spur gear include chemical transfer, cyclic operations, continuous production systems, both open-end, and closed loop. They are also well suited for pilot plants, vacuum systems, and metering application.

Product Description

Industrial Construction

At the heart of each ECO Gearchem pump are two tightly toleranced,machine-generated spur gears consisting of a drive and an idler gear.Self-priming capability is accomplished by our closely toleranced gears, which evacuate air from the suction piping. Gearchem pumps provide linear, pulsation-free flows, and the pumps are bidirectional. This easily allows the flow direction to be changed.

Application Expertise

Typical applications for this self-priming, external-spur gear include chemical transfer, cyclic operations, continuous production systems, both open-end, and closed loop. They are also well suited for pilot plants, vacuum systems, and metering application.

- Gearchem pumps offer laminar flows for consistent, continuous and measurable transfer or metering of liquids.

- Bi-directional

- Closed running and operating clearance evacuate air from the suction piping

- Can handle clear lubricating and non-lubricating fluids including hydrocarbons and polymers

- Variety of gears available and easily convertible to satisfy different service conditions

- All gear materials are non-sparking for use with hazardous fluids

- Internal sleeve type bearings are lubricated by process fluid eliminating the need for periodic lubrication maintenance and prevents contamination of external lubrication materials

- Three types of seals and two packing arrangements available

- Simplified maintenance due to quick dis-assembly

- Possibility of contamination of pumped fluid is eliminated

- Handles a variety of fluids and viscosities

- Superior chemical resistance

Eco IsoChem Brochure

Download